Discover the Success of DSE Monitoring

Introducing Our Valued Customers

At DSE Monitoring, we are honored to collaborate with a remarkable group of companies who are passionate about optimizing their operations. Together, we explore innovative solutions and pave the way for the future of efficient resource management, benefiting all stakeholders.

Read more

Explore the journeys of our esteemed customers as they embark on their optimization endeavors. Learn how they initiated their transformation, the challenges they overcame, and the remarkable outcomes they achieve today.

Join us in celebrating their successes and gaining valuable insights from their experiences. Together, we shape the landscape of intelligent monitoring and create a brighter, more sustainable future for all.

Do you have any questions?

Please feel free to call us: +44 (0) 20 3924 4447

– or send us an Email

Explore the journeys of our esteemed customers as they embark on their optimization endeavors. Learn how they initiated their transformation, the challenges they overcame, and the remarkable outcomes they achieve today.

Join us in celebrating their successes and gaining valuable insights from their experiences. Together, we shape the landscape of intelligent monitoring and create a brighter, more sustainable future for all.

Do you have any questions?

Please feel free to call us: +44 (0) 20 3924 4447

– or send us an Email

Food Industry

Empowering Orkla with Energy Optimization

Orkla, the leading food and confectionery company in Scandinavia

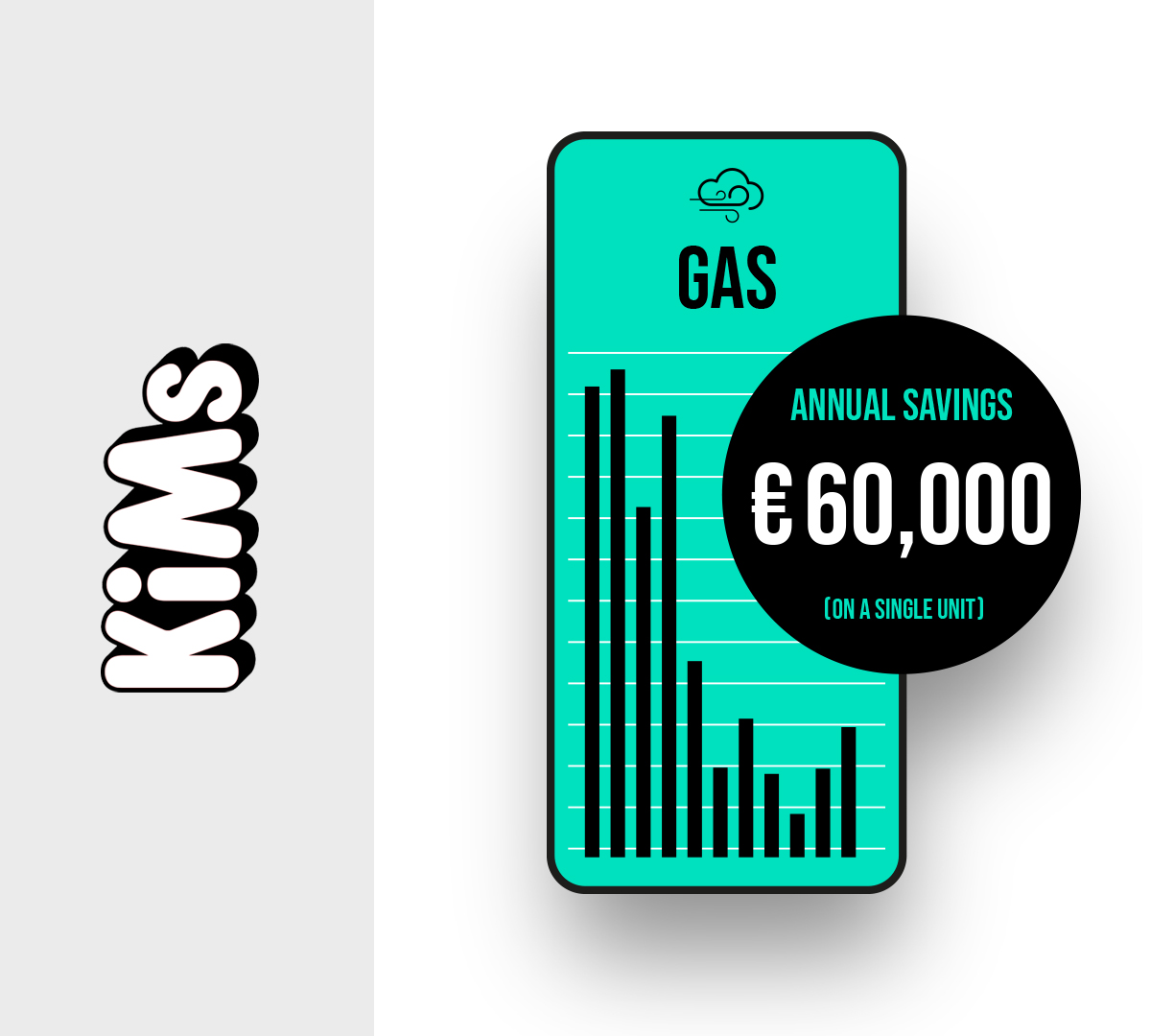

Orkla stands at the forefront of the industry with an impressive annual turnover of 5.7 billion euros. Within their portfolio, they own the renowned 100 million euro crisps brand, KIMs.

Recognizing the importance of energy optimization, KIMs has partnered with DSE Monitoring to drive significant savings and enhance their operational efficiency. With our advanced energy monitoring solution, KIMs can swiftly identify errors and detect instances of overconsumption.

By leveraging DSE Monitoring's technology, KIMs has successfully saved thousands of euros on their monthly gas bill alone. A case in point is when they discovered a defective cold water valve, a seemingly small issue that would have gone unnoticed without our energy monitoring capabilities.

Discover more about KIMs' experience and hear from Jesper Lauvring Hansen, the maintenance manager at KIMs, as he shares insights into the collaboration with DSE Monitoring and the remarkable outcomes achieved.

Join us on this journey of energy optimization and witness how DSE Monitoring empowers companies like Orkla to not only save costs but also leave a positive environmental footprint.

Eliminating Energy Waste for Thise Dairy

– worth 80,000 Euro per year on a single machine

Read more

Thise Dairy, renowned for delivering uncompromising organic quality products to the Nordic food cuisine, proudly holds the position of being the third-largest dairy in Denmark. Their commitment to excellence permeates every aspect of their raw materials and production processes.

To ensure optimal energy utilization, Thise Dairy has partnered with DSE Monitoring, harnessing the power of direct energy monitoring on their equipment and installations. This collaboration is nothing short of magical.

By leveraging DSE Monitoring's advanced monitoring solution, Thise Dairy has effectively put an end to energy waste. A striking example showcases the impact of this partnership: the detection of a broken pulley in a heat pump, a fault that could potentially cost a staggering €70,000 annually. Without the robust monitoring capabilities provided by DSE Monitoring, such an issue would remain undetected and cause significant financial loss.

Experience the transformative power of energy monitoring and witness how DSE Monitoring empowers companies like Thise Dairy to uncover hidden inefficiencies and make significant cost savings. Join us on this remarkable journey as we revolutionize energy management in the food industry.

Manufacturing Industry

Optimal efficiency realized reduces standby waste

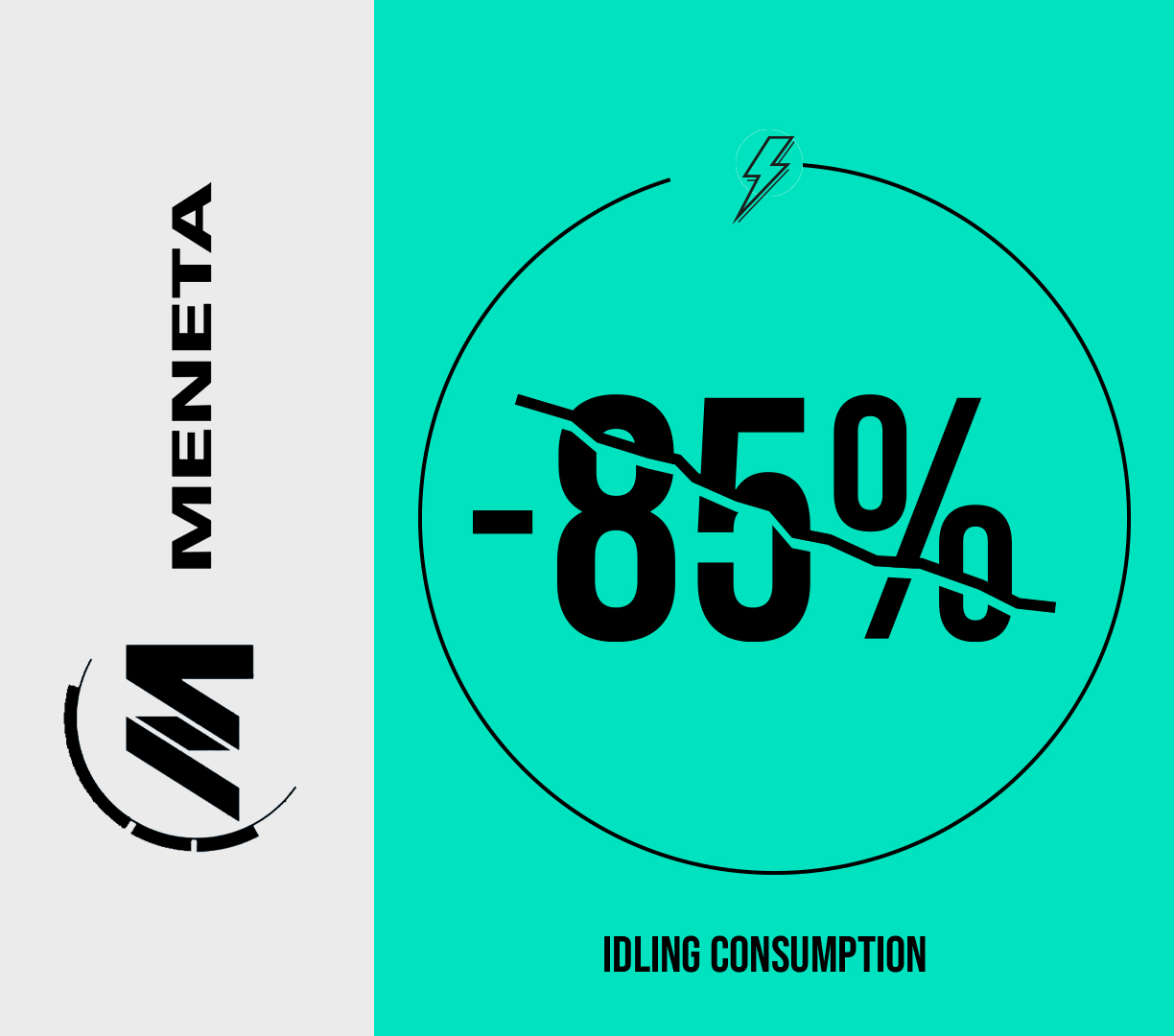

Meneta, the world's largest manufacturer of brake shims for cars

Meneta has an impressive annual turnover of 43 million euros, and is committed to responsible manufacturing practices. After implementing DSE Monitoring's advanced monitoring system, Meneta has experienced a remarkable transformation—they describe it as truly eye-opening!

With intelligent monitoring, Meneta easily identifies areas for improvement and eliminates waste. Through process optimization, they have achieved an impressive 40,000 euro annual savings in electricity expenditure.

Join Meneta on their journey towards enhanced efficiency and sustainability. Experience firsthand the power of DSE Monitoring's intelligent monitoring solution in unlocking substantial savings, fostering a greener environment, and creating a more prosperous future. Choose DSE Monitoring for optimal condition monitoring and take control of your utilities usage today.

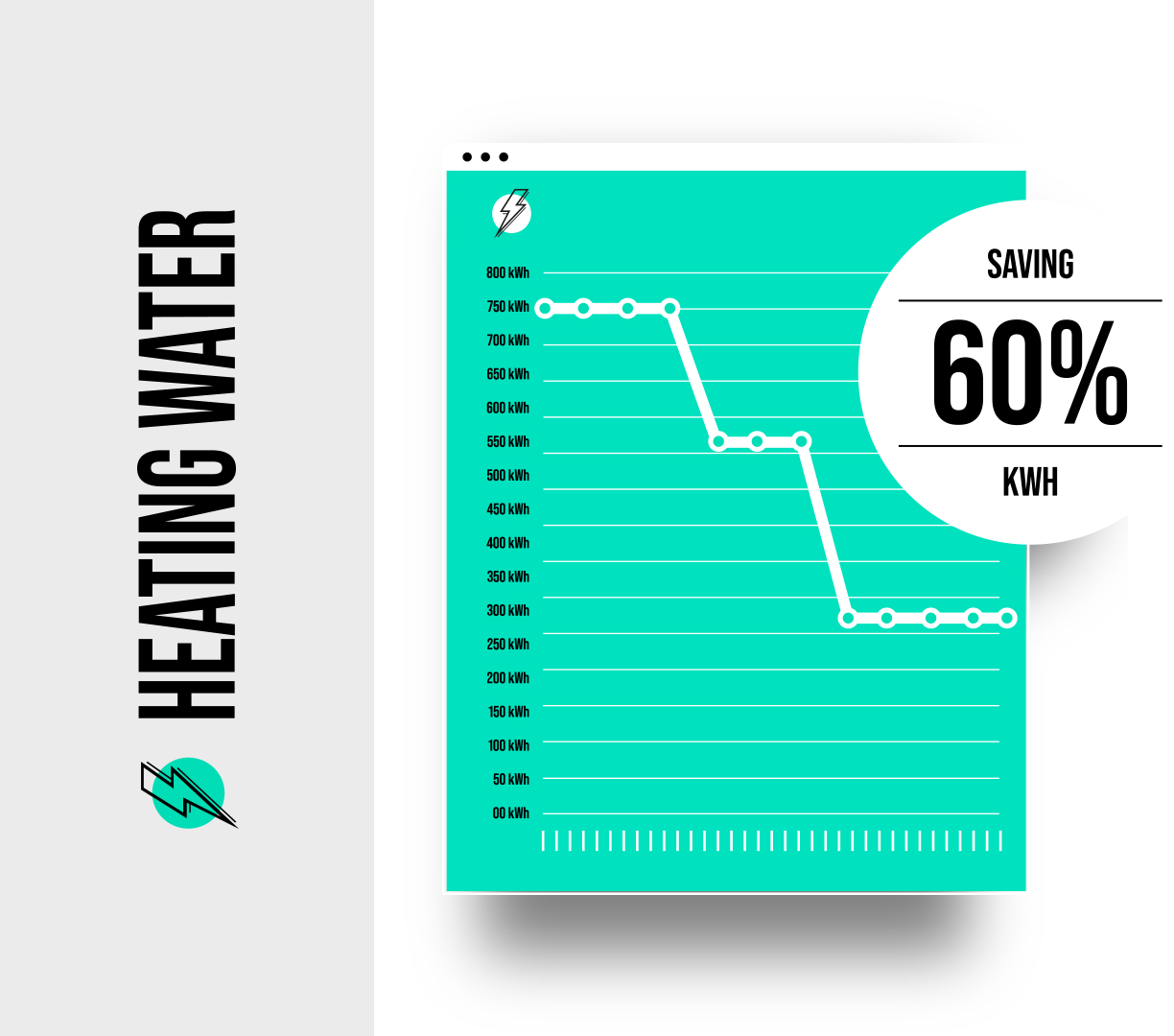

Monitoring = big savings

True data proves a 60% saving on operational energy cost (30,000 EUROS per year)

Read more

Among our customers, you find some of the most skilled and ambitious professionals within energy optimization, working at major manufacturing companies.

With live data monitored directly from their production equipment, they can easily and very efficiently document the effect of their energy projects, which makes DSE Monitoring a vital tool for them.

In this case, our customer replaced an industrial detergent on a degreasing facility for industrial parts. The new detergent was implemented, and the electricity savings reached 40% with an annual saving of 14,000 euros per year.

Leaks in compressor system detected

Sealed saving worth more than 30,000 euros per year

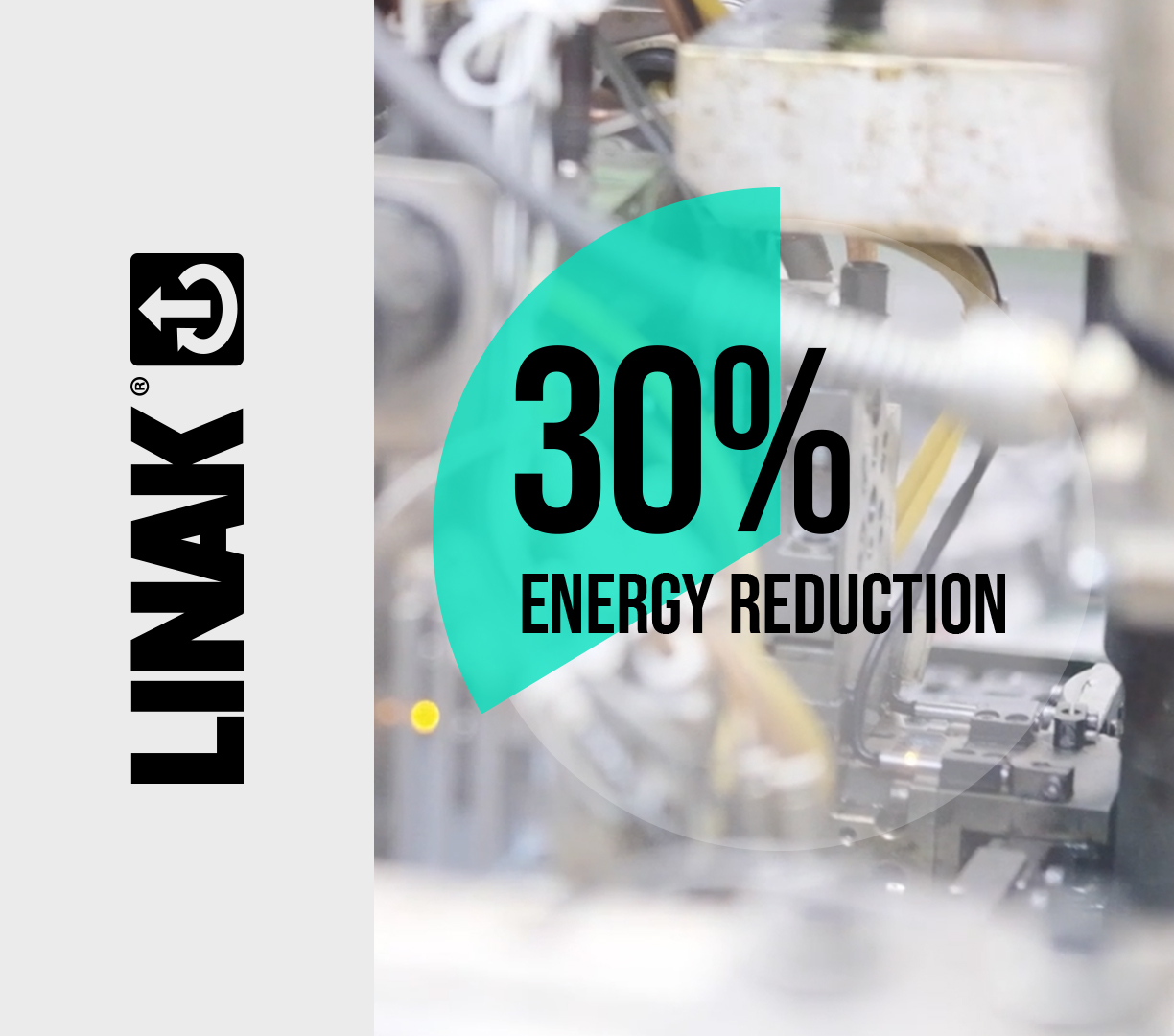

Linak is dominating the industry

Linak's leading technology within linear actuator solutions that ensure smooth adjustment in many different applications. 2,400 dedicated employees in 35 countries creating a 560 million euro turnover.

Linak is constantly working with energy optimization in their factories. When monitoring compressors, they cut more than 30% of their consumption on the biggest installation. That is worth 30,000 euros per year.

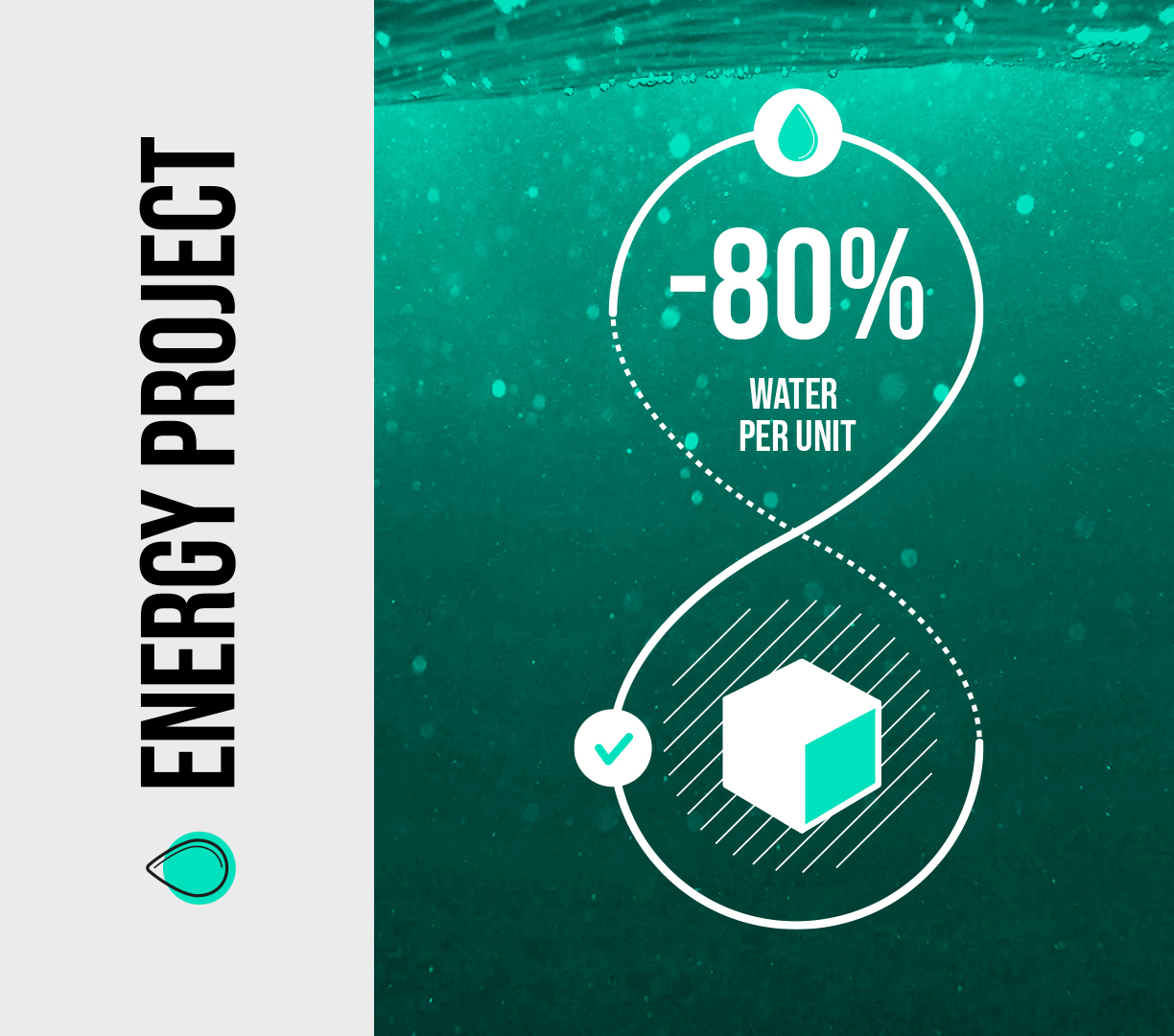

international fitting manufacturer saves 80% process water per unit

Read more

By combining consumption and volume into one “per unit”-measuring point, our customer is able to follow a key performance indicator in the production process. In combination with internal expert knowledge, they cut the usage of expensive demineralized water by more than 80% per unit.

When carrying out energy projects like this, it is important to be able to see the precise and current consumption. With live data directly from your equipment and installations, DSE Monitoring makes the process much easier, and you can document the immediate effect.

Facility Management

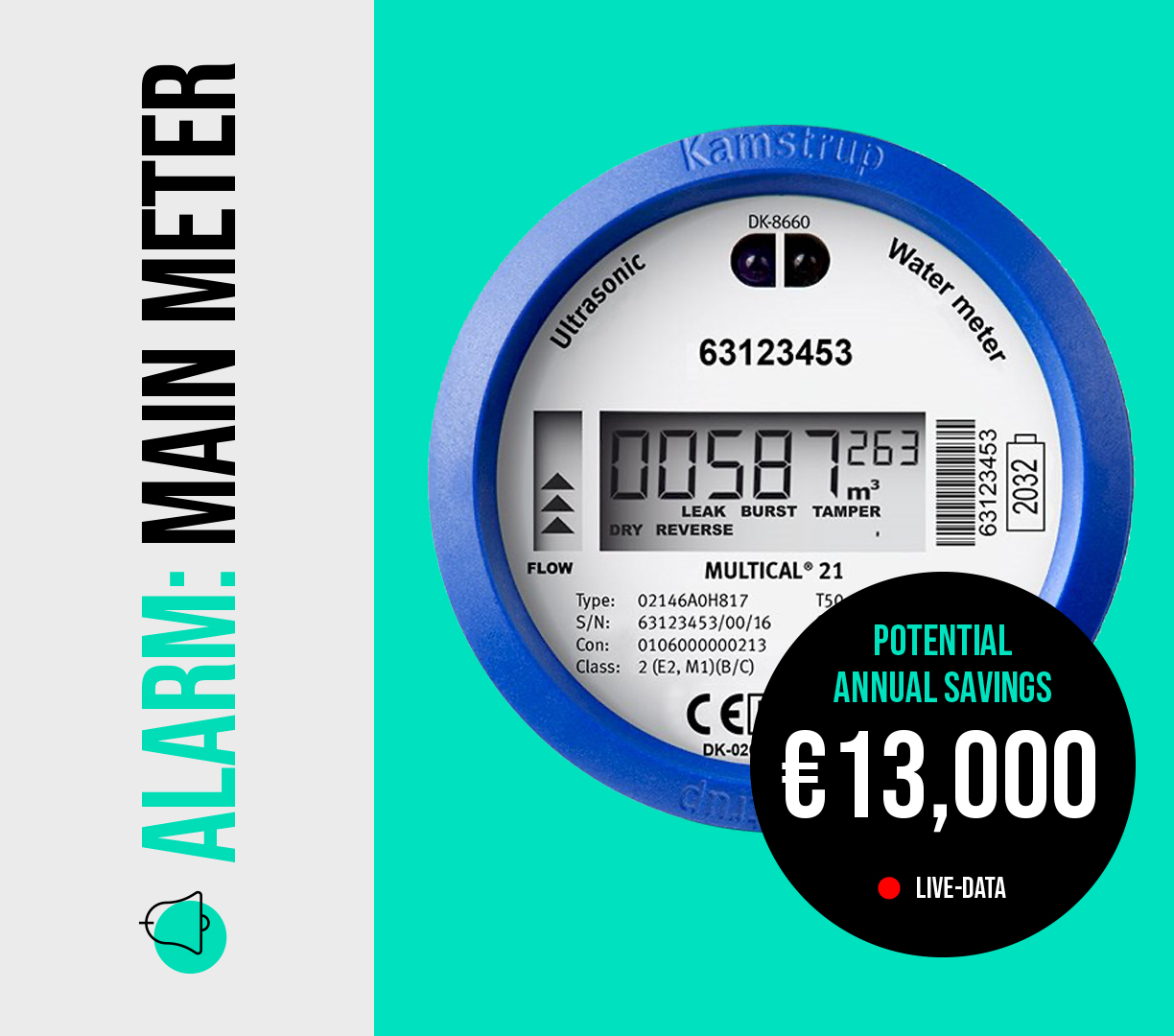

Main meter alarm prevents major leak

Read more

Without monitoring, a major leak would have gone undetected for days. The leak is next to impossible to detect since all the water runs in the pipes and directly down the drain.

BMS* failure detected

Read more

Like 95% of all our customers, this customer had great profitable benefits with DSE Monitoring within the first month.

After installing twenty measurement points directly on production equipment and installations, we quickly noticed one of the largest ventilation systems was running at full power on weekends and holidays, though no one was at work.

A minor defect in a control unit of the ventilation was identified. This was repaired in less than two hours, and the annual savings amounted to 30,000 euros.

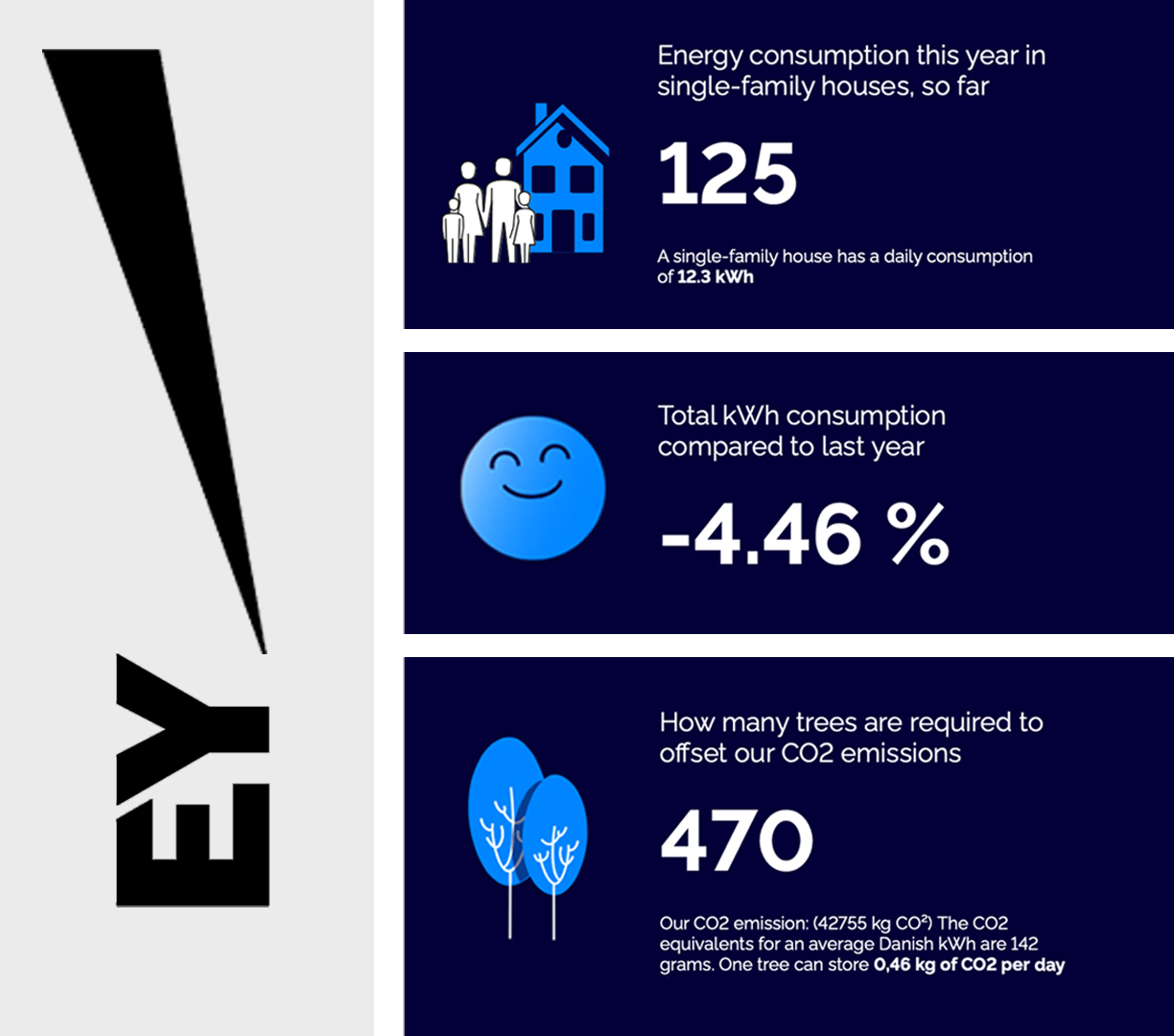

Complete transparency on utilities and carbon footprint

Ernst & Young (EY) has a total global turnover of €41.7 billion

EY is the third largest accounting firm on the planet. EY Nordic reflects this with a growth of 17.2% reaching an annual turnover of €360 million.

When you visit EY Nordic, you will be presented with live consumption data on flat screens. Explanatory data shows their consumption today compared to last year. How much their consumption corresponds to in households, and the CO2 emission in trees.

This shows that you care.

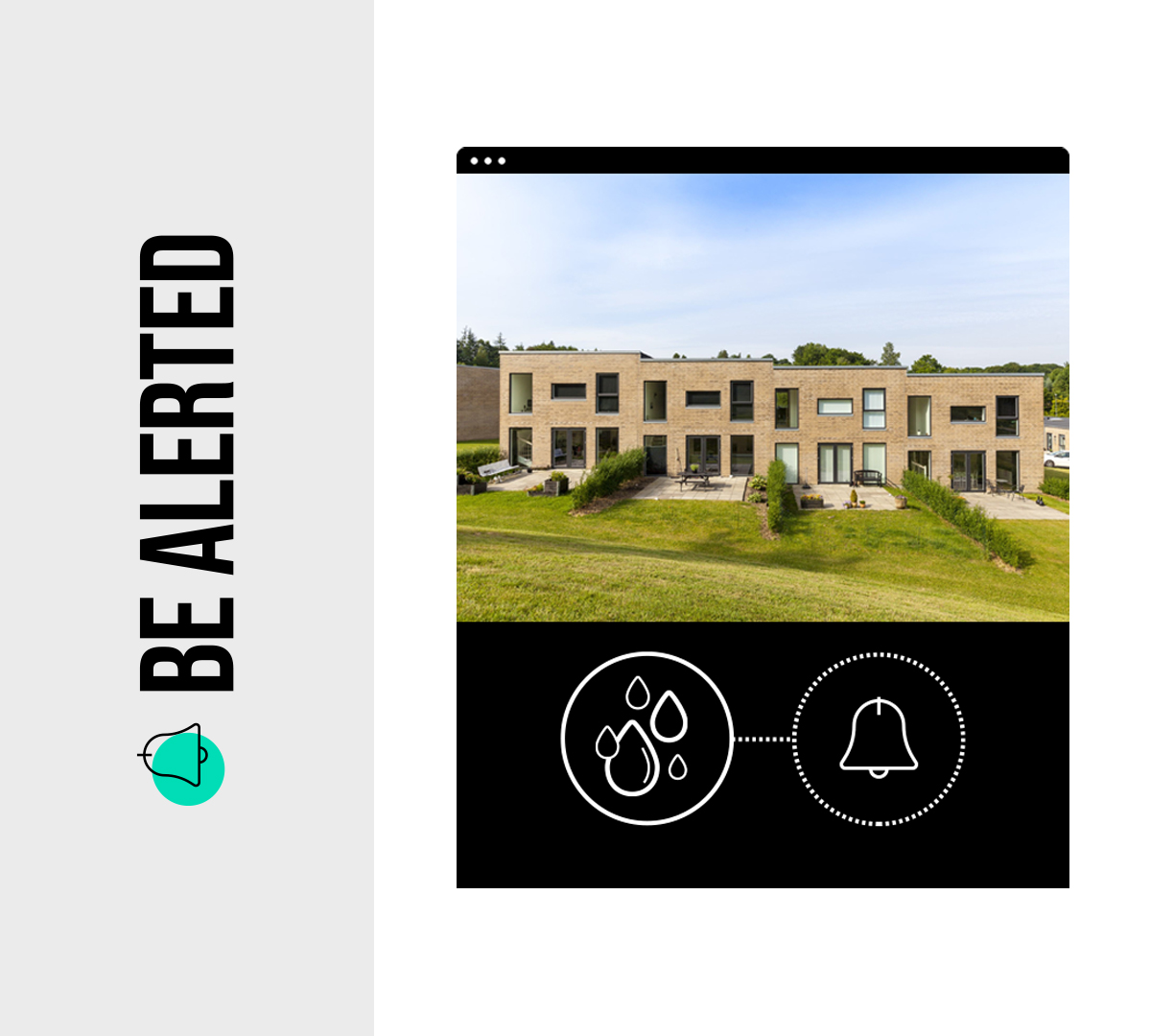

Alarm on Major water leak saves apartments worth 400,000 euros

Rene Birch a major private estate developer in Denmark

Rene Birch builds approx. 2,000 new homes every year. Last year his company “Birch Real Estate” was sold to English Aermont Capital.

Rene Birch believes that property should be managed based on data – also data from the actual buildings and residential units. He has worked with DSE Monitoring since 2017, and his facility department receives data from our energy management system both during construction and operation of the many thousand residential units.

Monitoring of properties provides a great and tangible value. In some cases, the savings of predicting accidents “before they happen” makes a difference. In this case, three brand new apartments worth 400,000 euros were saved from major water damage, by very simple monitoring.

Alarm on New Year's Eve saves facilities from comprehensive water damage

Read more

On New Year’s Eve, two alarms go off. A water pipe with hot water had burst, and now the hot water was gushing out onto the floor.

But the disaster was averted with humidity and temperature monitoring from our Energy Management System.

Do you like what you see?

Let's meet. It takes less than an hour to see and understand energy management with DSE Monitoring.

Please feel free to call us: +44 (0) 20 3924 4447

– or just send us an Email

FAQ

Is it time-consuming to get started with DSE Monitoring?

No, getting started is quick and efficient. If you place your order today, there is a fair chance that you will start receiving data on your screen by the end of the week.

With DSE Monitoring, installing a new measuring point is seamlessly integrated into your daily operations.

Is DSE Monitoring suitable for production, facility management, and housing?

Yes, DSE Monitoring is a versatile solution that caters to various sectors. In the manufacturing industry, we excel at measuring with exceptional accuracy and reliability. For facility management and housing,

DSE Monitoring seamlessly synchronizes with your existing systems and meters. You can even install new measurement points for parameters like humidity and temperature, consolidating all your data on one comprehensive platform.

Can DSE Monitoring be used internationally?

Absolutely! DSE Monitoring is trusted by large international companies requiring consumption monitoring across their factories, both domestically and abroad. Our solution enables effective monitoring and management regardless of geographical location.

What type of meters does DSE Monitoring use?

We do not limit ourselves to a single brand or type of meter.

At DSE Monitoring, we prioritize quality, accuracy, and reliability. Based on the specific requirements and environmental conditions, we carefully select the most suitable meters for your unique needs.

What is the LoRa network?

At DSE Monitoring, we primarily utilize the LoRa protocol, a wireless network, for all our installations. LoRaWAN (Long Range Wide Area Network) is a wireless communication protocol defined by the LoRa Alliance®.

Leveraging LoRa technology allows us to expedite the installation process without relying on existing networks.

Moreover, it provides an isolated, secure, and encrypted network, ensuring the availability and confidentiality of your data online.

How can I get started with DSE Monitoring?

At DSE Monitoring, we would love the opportunity to show you our solution. We have streamlined the entire process, making it incredibly simple. From selecting the right meters and equipment to collecting and monitoring consumption data across your production, facilities, and individual equipment, our system provides comprehensive oversight.

We seamlessly synchronize with your existing meters and systems. So, if you place your order today, it is highly likely that you can start reaping the benefits of high-end energy management within a week.

No answer to your question? Please do not hesitate to send us an Email

DSE Monitoring Ltd

Station Rd, Hampton, TW12 2BX

Call us: +44 (0) 20 3924 4447

Please feel free to send us an Email